Miniature linear motors for pharmaceutical and medical industry

- Miniature linear motors

- Green Drive linear motors

- Ironcore linear motors

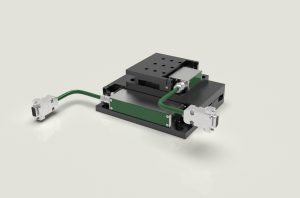

- Linear Units

- Accessories

- Anti-rotation mechanics for horizontal applications

- Anti-rotation mechanics with integrated pneumatic brake

- Cable Kit

- Cooling accessories

- For severe environment conditions

- Linear Coupling

- Linear Guide

- MagLift – Magnetic spring for vertical applications

- NL-NQ6D SIN/COS Interpolator

- Nuts

- Position feedback system

- Relative and absolute magnetic encoders

- Reversed Encoder

- Rotatable connector

- Terminal blocks with connectors

- Ultracompact Safety/measuring light curtain NiLAB NL-EB15

- → View all products →

- Brushless servo motors

- Servo Drive

- Controller

- Automation Software

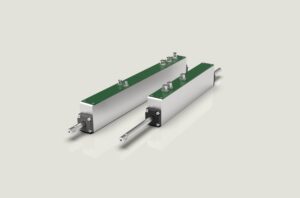

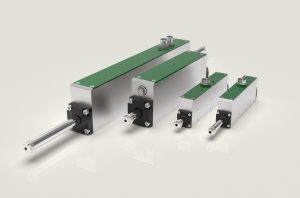

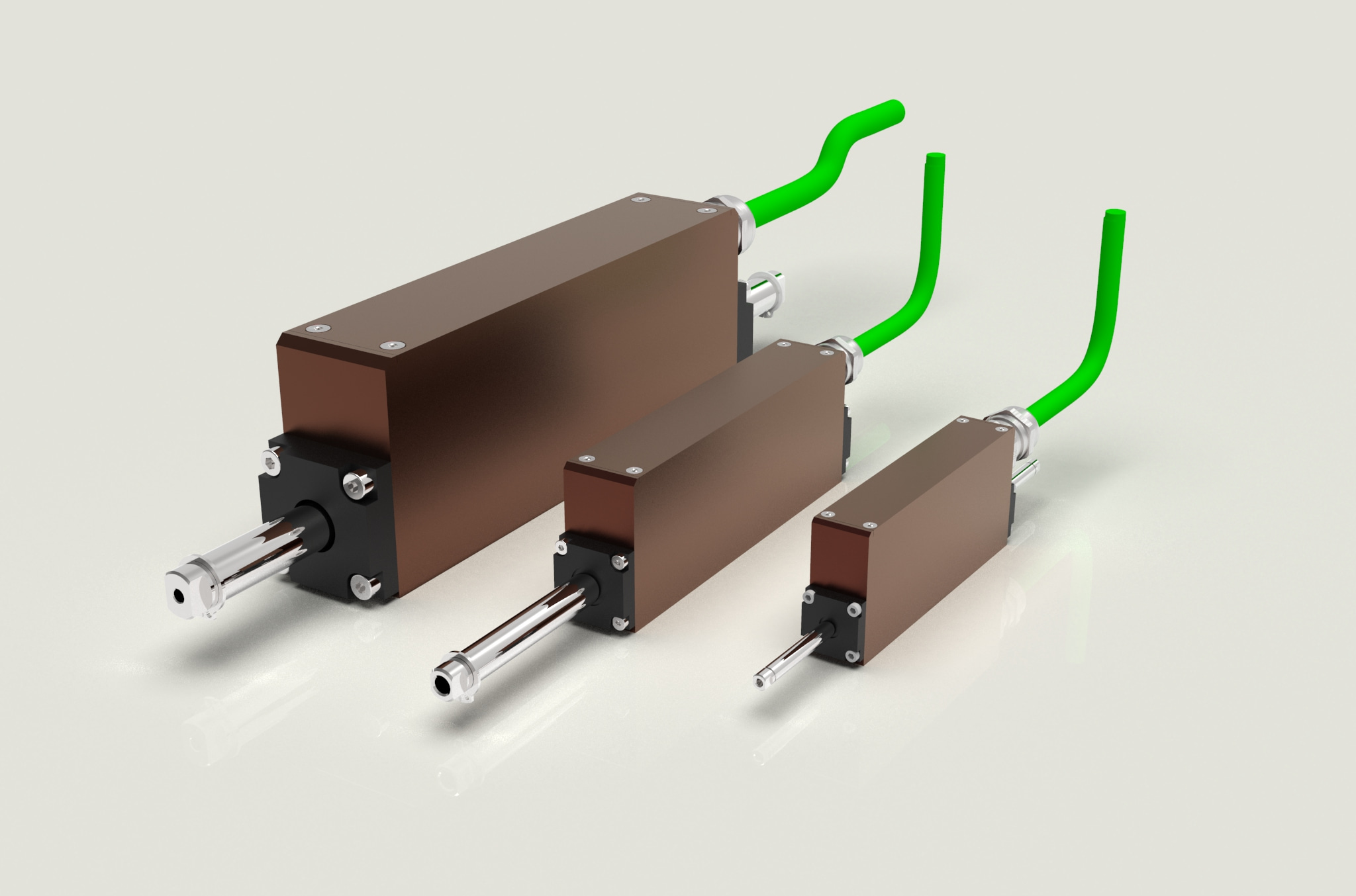

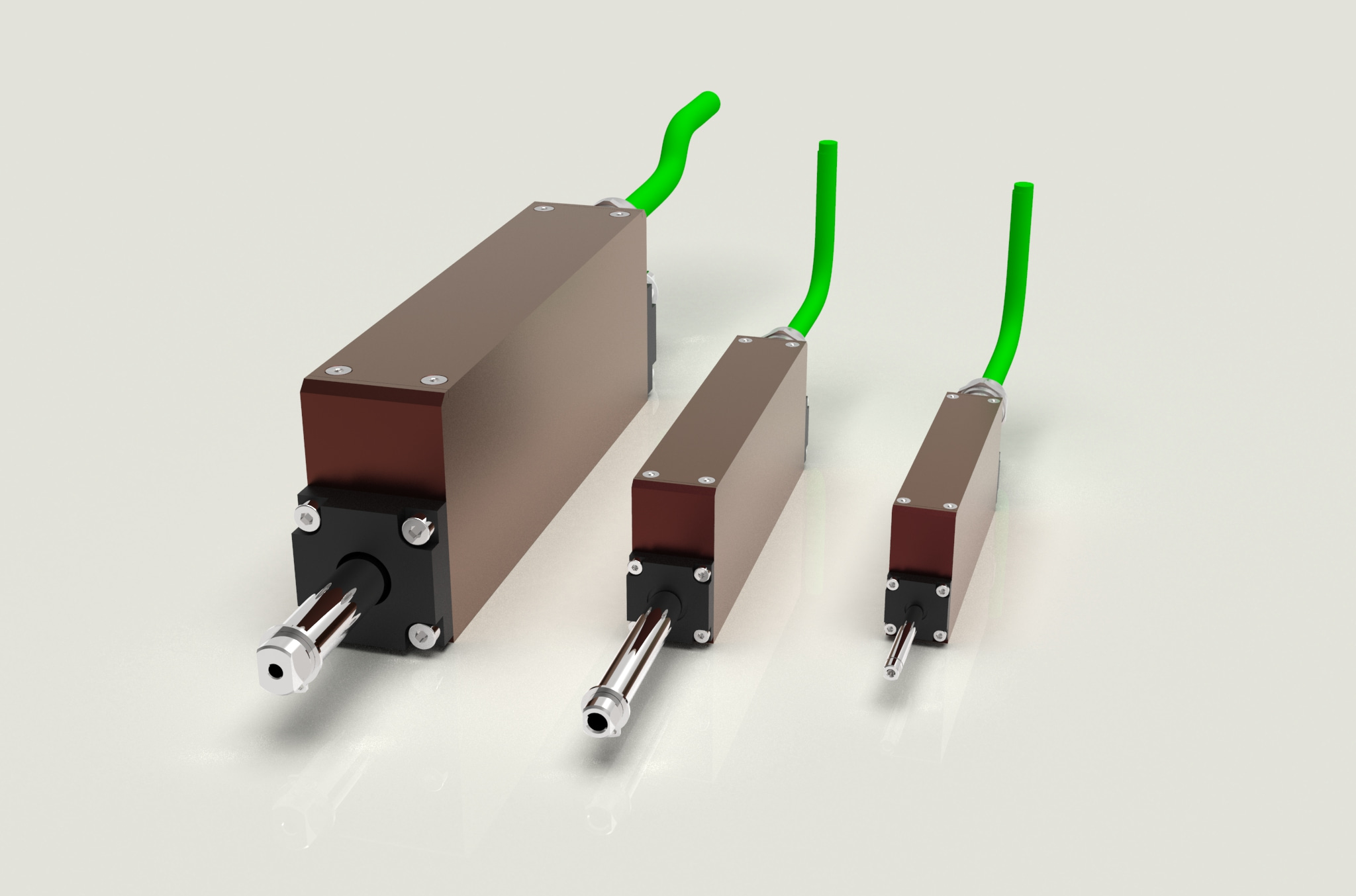

One of the advantages of the NLH series is its compactness with flange dimensions beginning from 15x34mm till 35x63mm. The linear motor is composed of a high performance three phase winding, an integrated encoder SIN/COS 1Vpp and a rod in AISI 304 stainless steel. The NLH series, composed of 6 different types, has an excellent performance and dimension ratio. The force range starts from 0,6 N up to 20 N of continuous force with peak forces 6 times these values. The standard power supply of the drive is 24/48 VDC.

The difference between the NL series and the NLH series is the G.H.A.®-coating*.

It is one of the most recent and innovative technologies applicable to the surface of all aluminium-base alloys. The surface is treated by a special anodic oxidation, with thickness ranging from 10 to 200µ, followed by the sealing of the micro porosities through silver ions (Ag+). The anodic oxidation of aluminium-base alloys is the safest protection treatment because it’s unremovable.

The G.H.A.® process (Golden Hard Anodizing) is patented (Patent No. EP1207220).

The advantages of the G.H.A. process are numerous:

- Highest corrosion resistance

- High antibacterial capacity and anti-mould (Antibacterial)

- Antistatic capacity

- Thermal conductivity

- Heat resistance

- Resistance to consumption

- Melting temperature: 2100 °C

- Hardness: 500-600 HV

- Suitable for direct contact with food

Therefore, aluminium alloys with the G.H.A.®-coating are considered an excellent alternative to expensive metals such as stainless steel or titanium alloys.

The miniature tubular linear motors of the NLH series with the innovative G.H.A.®-coating are specially designed for applications in the food, pharma and in the medical industry.

*Source: G.H.A. EUROPE S.R.L.